Hardware

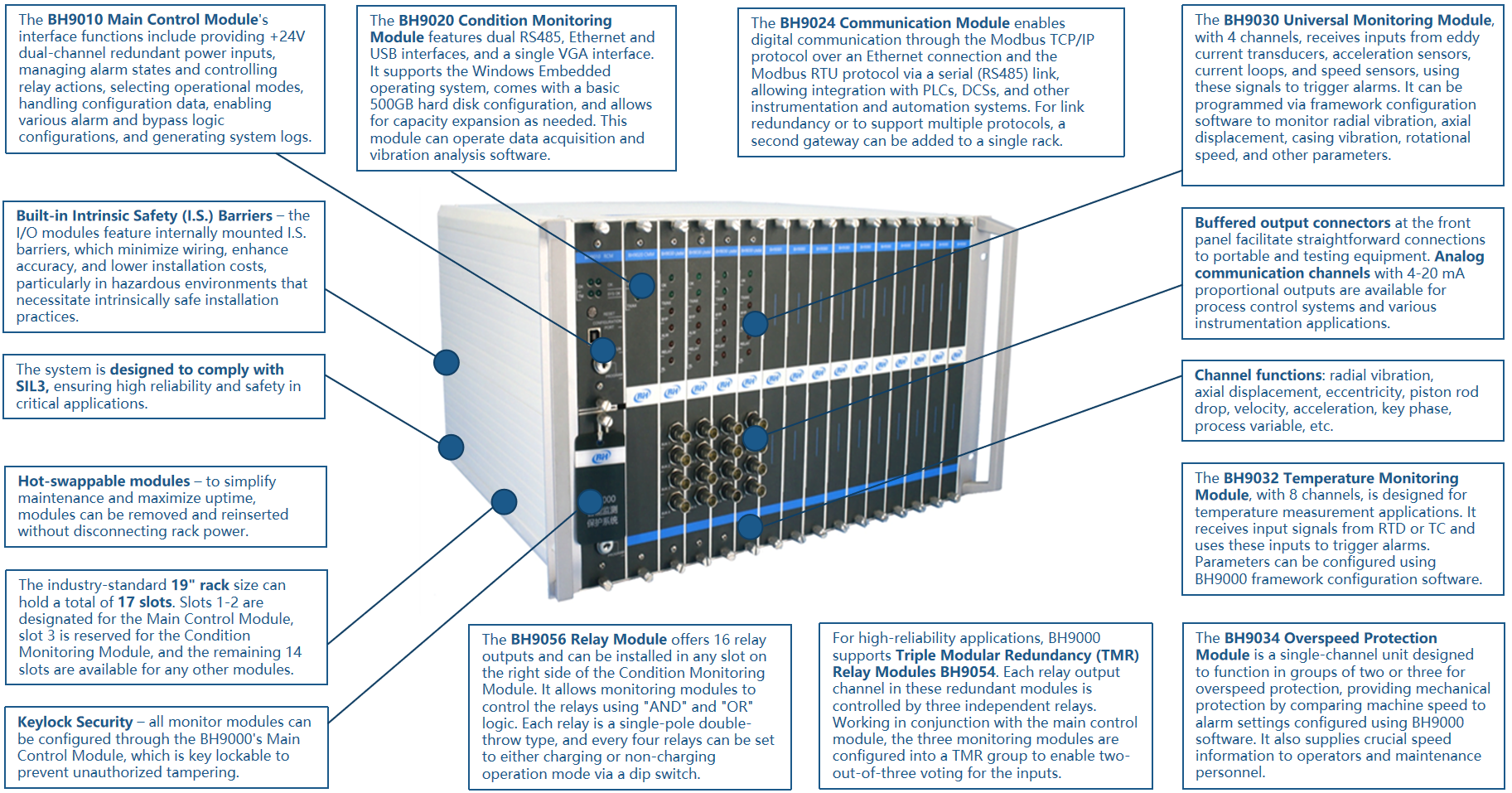

The BH9000 Machinery Protection System (MPS) integrates condition monitoring, fault diagnosis, and vibration protection into a single solution, ideal for safeguarding critical machinery. It continuously monitors key parameters, including Radial Vibration, Case Vibration, Axial Displacement, Phase, Speed, Eccentricity, Differential Expansion, Temperature, and Pressure. The system delivers reliable protection against catastrophic equipment failures while offering advanced analytical tools for early fault prediction and diagnosis.

System Summary

System Modules

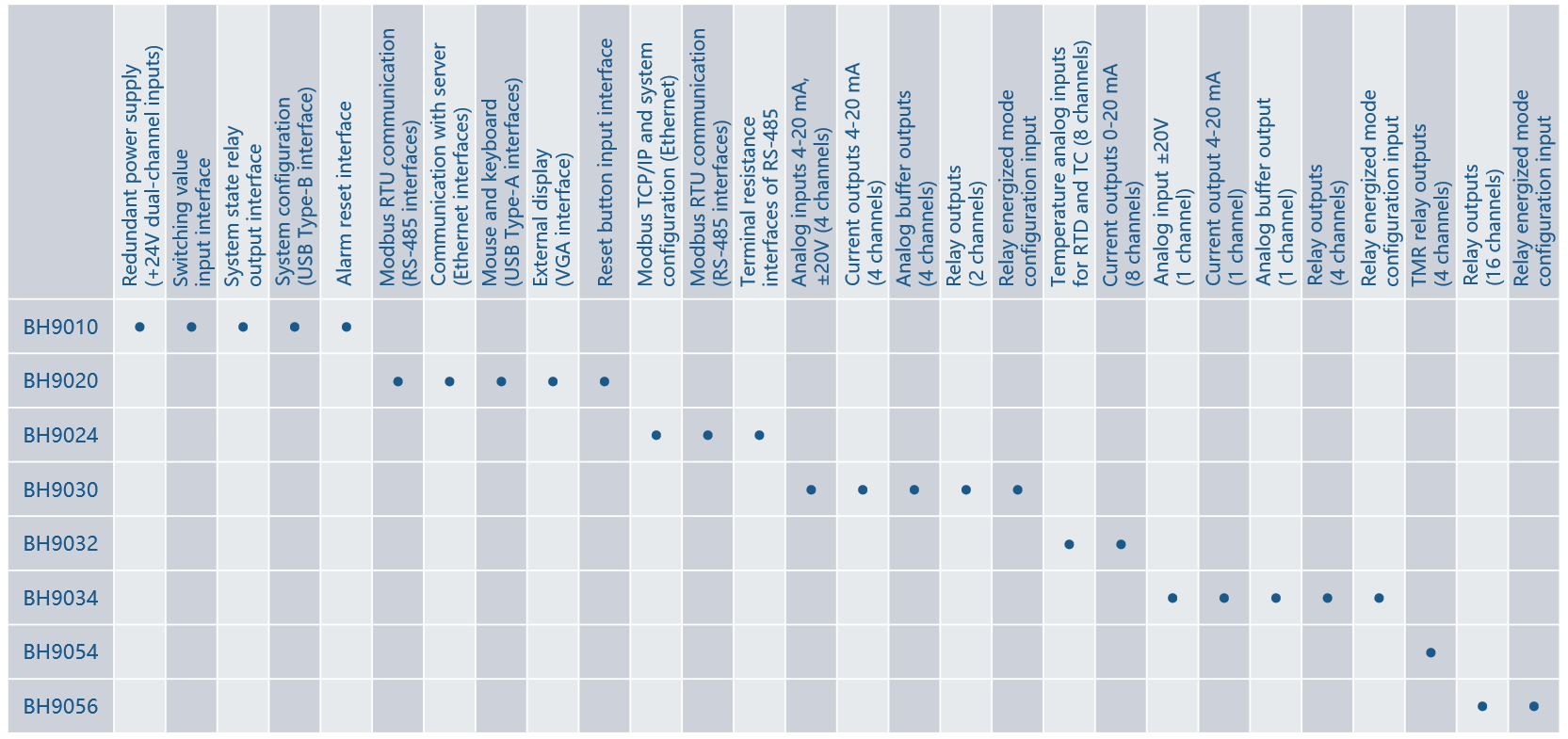

| Redundant power supply (+24V dual-channel inputs) | Switching value input interface | System state relay output interface | System configuration (USB Type-B interface) | Alarm reset interface | Modbus RTU communication (RS-485 interfaces) | Communication with server (Ethernet interfaces) | Mouse and keyboard (USB Type-A interfaces) | External display (VGA interface) | Reset button input interface | Modbus TCP/IP and system configuration (Ethernet) | Modbus RTU communication (RS-485 interfaces) | Terminal resistance interfaces of RS-485 | Analog inputs 4-20 mA, ±20V (4 channels) | Current outputs 4-20 mA (4 channels) | Analog buffer outputs (4 channels) | Relay outputs (2 channels) | Relay energized mode configuration input | Temperature analog inputs for RTD and TC (8 channels) | Current outputs 0-20 mA (8 channels) | Analog input ±20V (1 channel) | Current output 4-20 mA (1 channel) | Analog buffer output (1 channel) | Relay outputs (4 channels) | Relay energized mode configuration input | TMR relay outputs (4 channels) | Relay outputs (16 channels) | Relay energized mode configuration input | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BH9010 | • | • | • | • | • | |||||||||||||||||||||||

| BH9020 | • | • | • | • | • | |||||||||||||||||||||||

| BH9024 | • | • | • | |||||||||||||||||||||||||

| BH9030 | • | • | • | • | • | |||||||||||||||||||||||

| BH9032 | • | • | ||||||||||||||||||||||||||

| BH9034 | • | • | • | • | • | |||||||||||||||||||||||

| BH9054 | • | |||||||||||||||||||||||||||

| BH9056 | • | • |

System Functions

Data Acquisition

The BH9000 system continuously and synchronously collects, analyzes, and stores various input signals. It automatically identifies the operating status of the equipment, such as startup/shutdown, speed ramp-up/down, and normal or abnormal conditions, and adjusts data collection based on the equipment's status.

Data Analysis

The BH9000 features advanced vibration analysis capabilities, including Waveform, Amplitude, Spectrum, Phase, Envelope Demodulation, Shaft Orbit, Shaft Position, Waterfall, Bode, Polar, Cascade, and P-V plots.

Protection Function

When there is an abnormality in the machine, the system drives relays output according to the logical operation which is set inside system to shutdown machine to avoid greater losses.

Current Output

Each input channel corresponds to a 4-20 mA output, which converts the sensor measurement value into a current signal for PLC, DCS or others.

Event List

Records alarm events and system events. The list of events allows you to recognize the status of the BH9000 at the moment of the event.

System Showcase

The BH9000 has been applied in hundreds of sets.

Wired System

The BH7000 Data Collector is a key hardware component designed for condition monitoring systems. Its modular design allows it to serve as a versatile scenario. By combining different modules, the BH7000 can be used across a wide range of machines.

- System Features

- Modular design with dedicated input modules for different signals.

- Supports flexible signal combinations, including IEPE, Inductive sensors, Eddy Current sensors, Photoelectric sensors, 4-20mA, ±21V, PT100, and more.

- Enables multi-channel data acquisition with continuous, full-cycle, and synchronous capabilities.

- Adjustable sampling rates range from 2.56kHz to 256kHz.

- A/D conversion with a minimum resolution of 24 bits.

- Certifications: CE, FCC, IC, CCC, and EX.

- System Modules

| System Control | TCP/IP | RS485 | Acceleration | Velocity | Proximity | Temperature (PT100) | Temperature (Volt) | Strain | Keyphase (Proximity) | Keyphase (NAMUR) | Keyphase (Photoelectric) | -21V~+21V | 4-20mA | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BH7010L | ● | ● | ● | |||||||||||

| BH7020 | ● | ● | ||||||||||||

| BH7021 | ● | ● | ● | |||||||||||

| BH7022 | ● | |||||||||||||

| BH7024 | ● | |||||||||||||

| BH7028 | ● | ● | ● | |||||||||||

| BH7030 | ● | |||||||||||||

| BH7042 | ● | |||||||||||||

| BH7043 | ● |

Wireless System

Wireless systems offer fast and easy installation and have been widely used in non-critical machinery applications. With various communication technologies available, these systems can be selected based on specific requirements. They measure both vibration in tri-direction and temperature, capturing not only values but also waveforms and temperature data.

- Products catalog

- Wireless Sensor (Without Gateway)

- BH306-10

- Protocol: NB-IOT

- Wireless Sensor (Without Gateway)

- BH306-12

- Protocol: 4G/5G

- Wireless Sensor (With Gateway)

- BH306-08P

- Protocol: Lora Based

- Wireless Gateway

- BH3002P

- Protocol: Lora Based

- System Features

Easy Installation

- Plug and Play

- No Cable

- Bluetooth Setup

Superb Battery Life

- Ultra-Low Power Consumption Algorithm

- Large Capacity Battery

Cloud-Edge Collaboration

- AI Model Interaction

- Proactive Sensor Alarm

- Automatic Diagnosis

Cloud Control

- Remote Sensor Setup

- OTA

- Scenario

Portable device for on-site equipment inspection management, is an “offline” data collection system. Collected data can be imported into the enterprise database management system. It is an auxiliary tool for standardizing and digitizing the equipment management of enterprises. It performs offline monitoring of equipment without online monitoring systems and can seamlessly integrate with online monitoring systems to build a unified monitoring platform.

Bohua offers a range of sensors including Acceleration sensors, Vibration-Temperature Sensors, and Proximity sensors, designed to meet the needs of condition monitoring and vibration protection.

- Accelerometer

- Dual-output Sensor

- Proximity Sensor